Ethylene Oxide (EO) Sterilizers

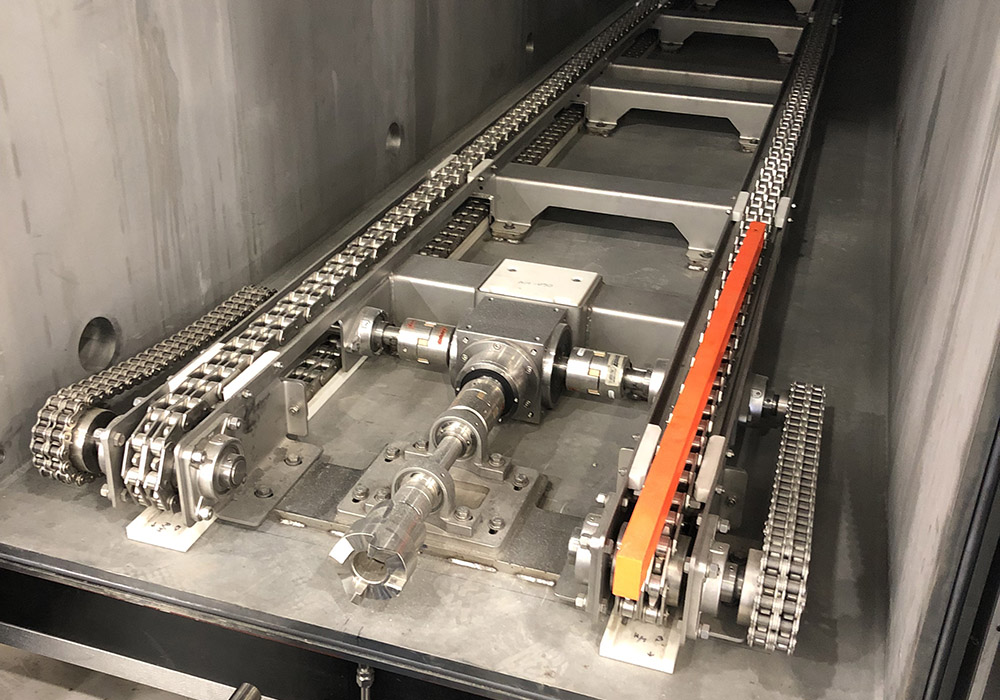

Since 1969 ETC has been manufacturing industrial Ethylene Oxide (EO or EtO) sterilizers, delivering some of the industry’s most sophisticated and largest ethylene oxide sterilizers in the world. ETC can also provide and integrate automation systems, pallet conveyance systems, preconditioning and aeration room/cells in accordance with your requirements.

Ethylene Oxide (EO) Sterilizers

Since 1969 ETC has been manufacturing industrial Ethylene Oxide (EO or EtO) sterilizers, delivering some of the industry’s most sophisticated and largest ethylene oxide sterilizers in the world. ETC can also provide and integrate automation systems, pallet conveyance systems, preconditioning and aeration room/cells in accordance with your requirements.

Turnkey EO sterilizer systems

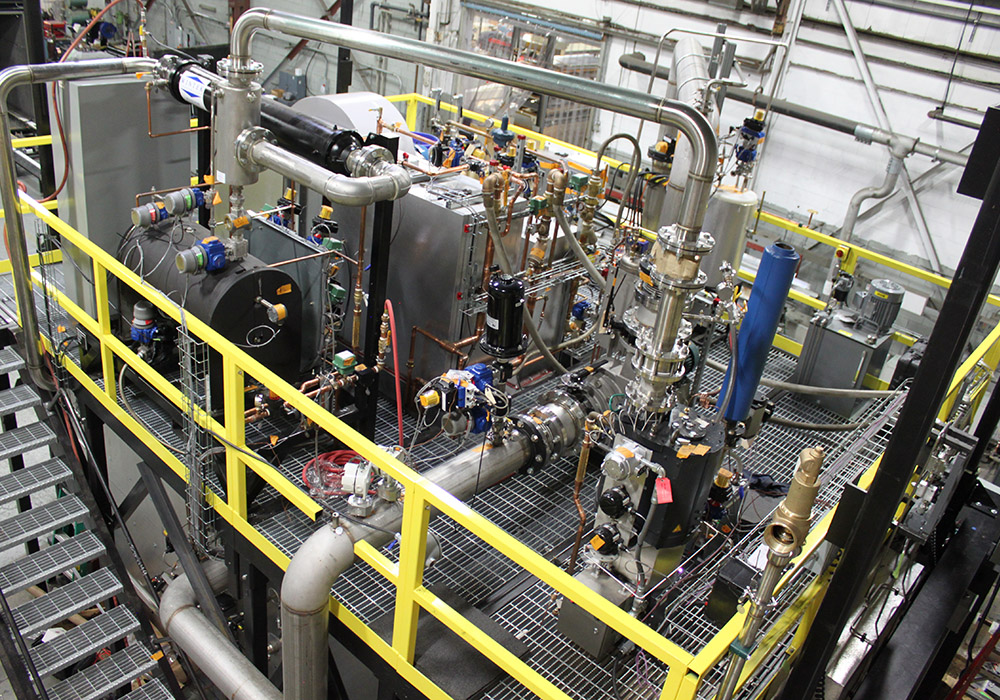

For over five decades, ETC has accumulated rich technical resources and experience designing, manufacturring, testing, and installing complete turnkey ethylene oxide sterilization systems, ensuring each sterilizer is fully factory-tested and delivered with a comprehensive documentation package that supports site validation efforts.

PRESSURE VESSEL TECHNOLOGY

ETC maintains an ASME certified weld shop. We have the capability and flexibility to meet your needs:

- 53 ft3 to 6,000 ft3

- ASME-PVHO certified and stamped

- Rectangular or cylindrical

- S/S construction

- Wide range of finishes

- Floor or pit mounted

- Standard 15 year vessel warranty (Air jacketed, water jackets must be SS)

- Availability of sectional chambers

IN-HOUSE TESTING

All ETC sterilizers are subjected to in-house testing which include the following:

- ASME Hydro Testing

- Vacuum Leak Testing

- Vacuum Performance Testing

- Pressure Leak Testing

- Complete I/O Verification

- Temperature Distribution & Wall Map Testing in accordance with ISO11135

- Door Operational Test

- Operational System Testing

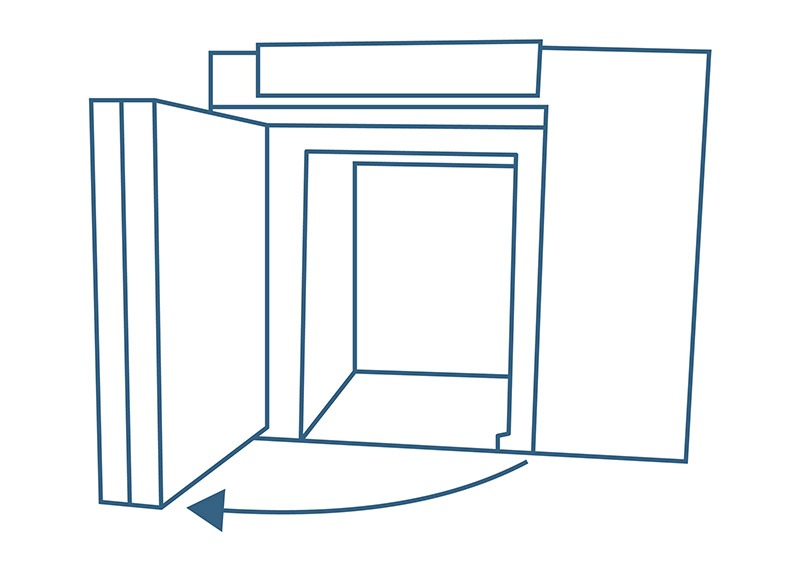

DOOR CONFIGURATIONS

ETC offers three unique door designs as standard configurations, eliminating the added cost associated with a customization of the autoclave design. By offering a choice of three designs, it enables our clients to select the best door type that will meet their needs. Each door type has its pros and cons which must be considered before selecting the door type for your facility.

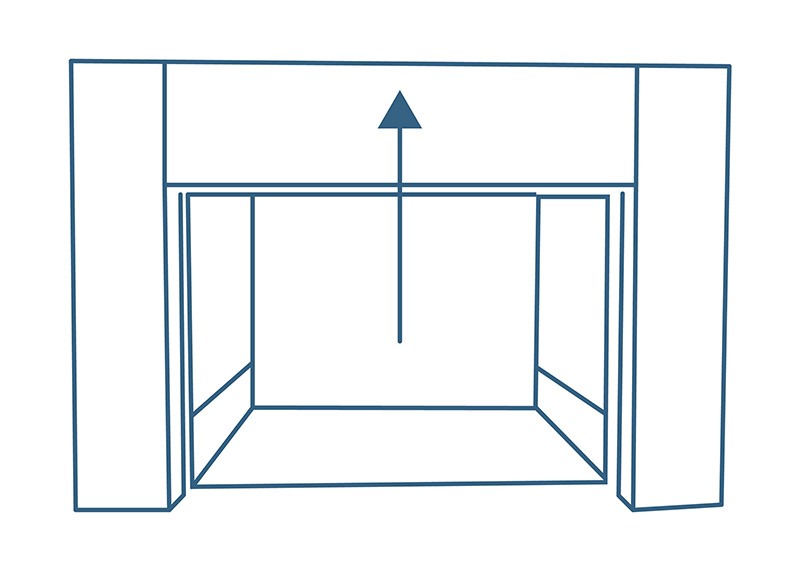

Vertical Rising Door

- Ideal for new construction where interstitial mechanical space is available

- Allows for load staging in front of door

- No loading plates/ ramps required

- Minimal mechanical parts

- Smooth and quiet operation

- Uses less square footage than horizontal sliding doors

- Requires a smaller pit than horizontal sliding doors

- Door Is retained behind heavy-duty door guides during opening

- Requires backup pressure for door seals if power fails

Roller Locking Hinged Door

- The oldest of the door designs with proven performance.

- Uses less permanent square footage than horizontal sliding or vertical doors

- Requires the smallest pit

- Smooth and quiet operation

- Provides positive mechanical locking for the door seal (critical for BSL3 &BSL4)

- Door is retained behind heavy duty blocks when unlocking

- Requires internal or external loading plates/ramps (provided for pit mounting only)

- Loads cannot be staged in front of door

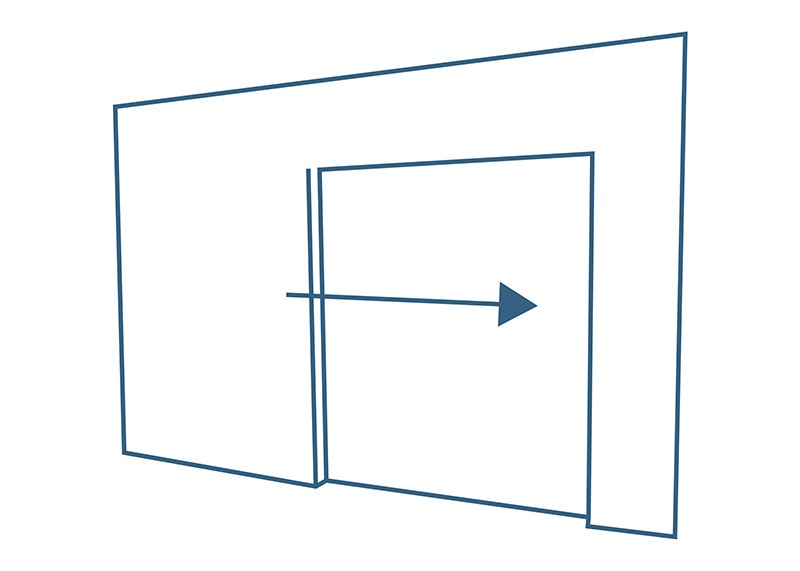

Horizontal Sliding Door

- Ideal for existing or new construction where adjacent space is available

- Requires the largest square footage

- Requires a larger pit than hinged or vertical doors

- Allows for load staging in front of door

- Smooth and quiet operation

- No loading plates/ ramps required

- Minimal mechanical parts

- Requires backup pressure for door seals if power fails.

AIR JACKETED SYSTEM

One of ETC’s most premier innovations is the use of our chamber jacket heating system. ETC utilizes a hot air jacket chamber instead of a hot water jacket chamber heating system. The application of this unique design approach offers many significant safety and maintenance advantages over our competitions hot water jacket systems.

The hot air, closed loop heating system is designed to uniformly blanket the chamber and doors to maximize heating efficiency and temperature uniformity to meet the requirements of ISO standard 11135. This system achieves a temperature uniformity of +/- 3° C of the pre-programmed control set point and gets there in less than three hours from an ambient room temperature of 21° C.

- By the utilization of heated air instead of a water-jacketed system, substantial savings are achieved in energy costs throughout the lifecycle of the sterilizer. Depending on the system design and the size of the chamber, the amount of energy required to heat and maintain the temperature of the water in a hot water jacket system alone, exceeds that of the product load.

- A dry, hot air jacket heating system eliminates the corrosion and other maintenance concerns associated with water-jacketed systems.

- Water jacket systems require additives that must be constantly monitored and balanced to slow down corrosion, and impose maintenance requirements that add to life-cycle operating costs.

- Small leaks that may develop over time in a hot air heated system are not detrimental to the performance of the sterilizer temperature control and are easily repaired. Water leaks create operation and temperature performance problems, as well as maintenance hazards. Seals on such items as water pumps must also be constantly checked and replaced regularly, increasing maintenance costs and downtime.

- ETC’s air jacketed systems are inherently lighter than equivalent water-jacketed systems and this enhances heating and cooling distribution. Additionally, because of their reduced weight, they are more easily manipulated for rigging and installation. Shipping costs are also reduced due to a lighter weight chamber.

- The air jacket system is capable of heating and cooling of the chamber and can control the chamber within the range of 80 - 150° F to suit cold or conventional EO cycle requirements

KEY FEATURES

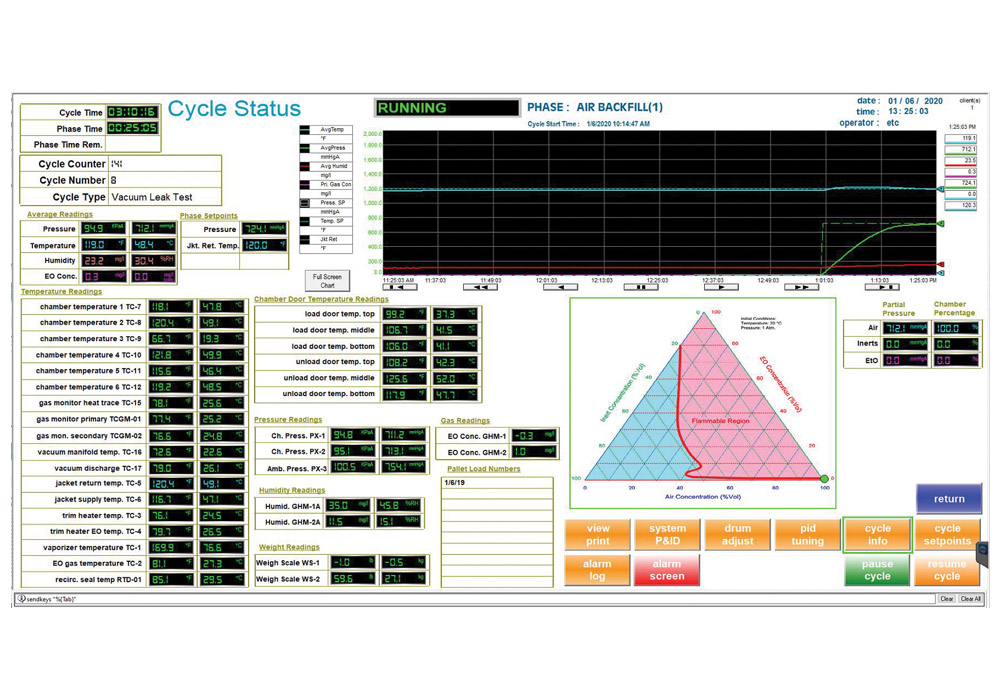

Robust Control Systems

ETC's control systems are capable of replicating any process and are designed for contract sterilization environments/facilities and medical manufacturers. From full SCADA control systems with a PC based HMI with advanced features and reporting capabilites to Panel View HMI systems with thermal printers. We can build to your needs.

Cost-effective Design

ETC offers several flexible designs as standard configurations, eliminating the added cost associated with a custom design. Let us assist you in selecting the most ideal unit, according to your unique needs.

WHAT MAKES ETC DIFFERENT?

Since 1969, ETC Sterilization Systems has designed, manufactured, and installed EO and Steam sterilizers under one roof, right here in the United States. Our capabilities provide the proper size chamber for optimum sterilizer performance and utility consumption that meet or exceed your specifications.

Learn More