Autoclaves and Steam Sterilizers

Steam sterilization or autoclaving is not a new process but it is proven, dependable, safe and environmentally friendly. It is also important to note that it is not appropriate for all materials due to the process being high temperature and high pressure. However, for those products that it is right for, there is not a more efficient process. When selecting a sterilizer it is important to make sure you are getting a unit that fully meets your needs – after all, a quality autoclave will be in use for 20 years or perhaps longer. At ETC all of our units are made to order, which means you get the right autoclave based on your specific facility, available space, and type of operations being conducted.

Autoclaves and Steam Sterilizers

Steam sterilization or autoclaving is not a new process but it is proven, dependable, safe and environmentally friendly. It is also important to note that it is not appropriate for all materials due to the process being high temperature and high pressure. However, for those products that it is right for, there is not a more efficient process. When selecting a sterilizer it is important to make sure you are getting a unit that fully meets your needs – after all, a quality autoclave will be in use for 20 years or perhaps longer. At ETC all of our units are made to order, which means you get the right autoclave based on your specific facility, available space, and type of operations being conducted.

Customized cycles are available

ETC can offer a variety of sterilization cycles to meet your needs. We can provide cycles for everything from liquids (sealed and open containers), animal feed, animal bedding, linens, medical/research waste and instruments. Additionally, ETC can provide customized cycles for specific loads, where standard cycles may damage or compromise the integrity of the load.

Largest selection of steam sterilizer chamber sizes

ETC offers over 60 cross sectional sizes ranging from mini bulk (36” W x 42” H) to bulk sized units (36"W x 84”H, 48”W x 84”H, 62”W x 84”H, 72”W x 84”H 84”W x 84”H, 102”W x 72”H and more).

We also manufacture custom size autoclaves if you have a particular need that a standard size will not work. If you need to sterilize something that is an unusual shape we can manufacture an autoclave that is an ideal size.

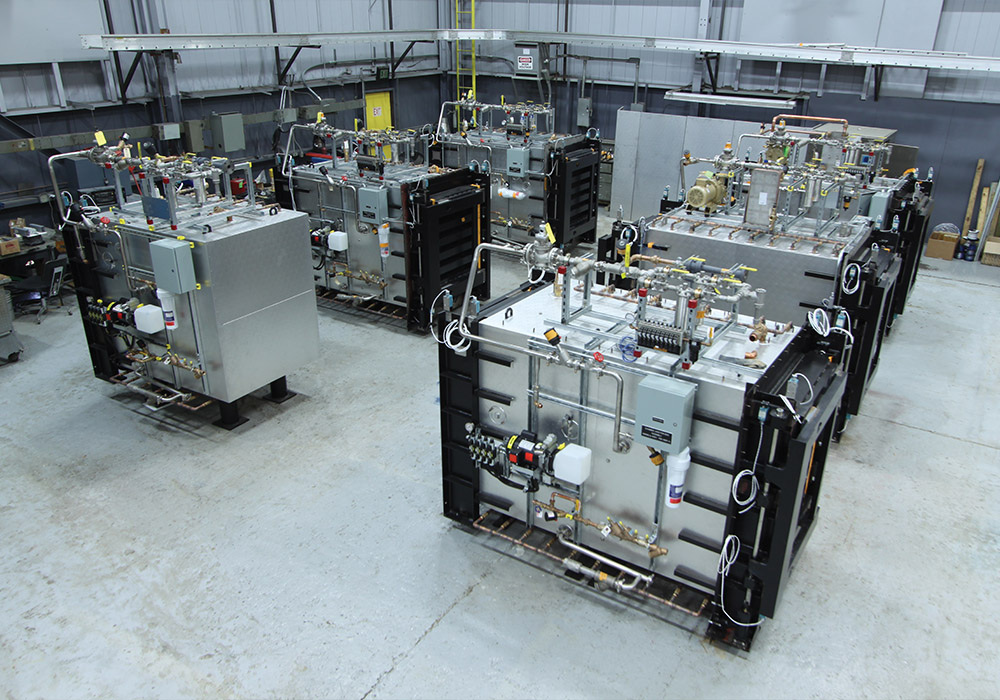

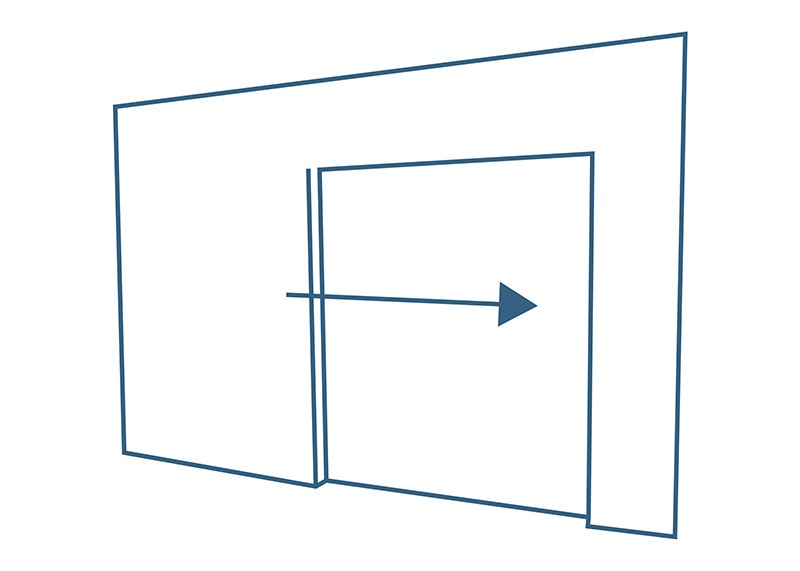

Sectional Design

In 2005, ETC was first to design and install a fully welded- in-place bulk autoclave in a difficult to access location in a facility. ETC’s process for installing Bulk Size units in basements, on upper floors, and in other challenging facility locations is based on protocols that have been developed and modified, as required, in conjunction with pre-inspections of the specific sites. Since each facility is different, the site pre-inspection is key in determining number of modular sections, physical chamber size, and door types. The Sectional Design can be provided in 2 - 4 modular sections, if required.

ETC’s sectional autoclaves eliminate the need for rigging full size units through openings in facility walls or roofs, removal of doors or frames, costly facility modifications and major disruptions to everyday business activities surrounding the installation. Each section is delivered to the final destination with no additional modifications.

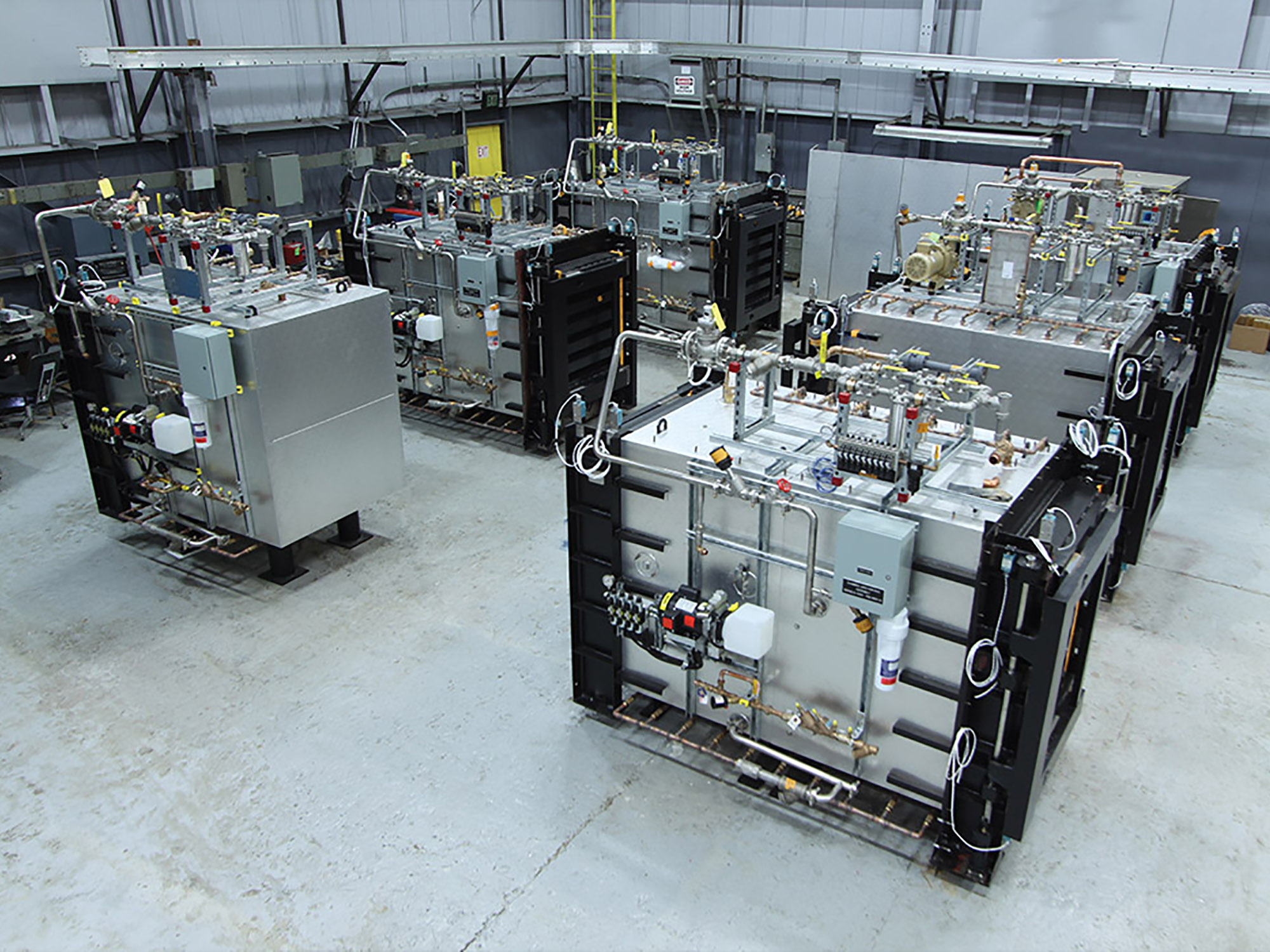

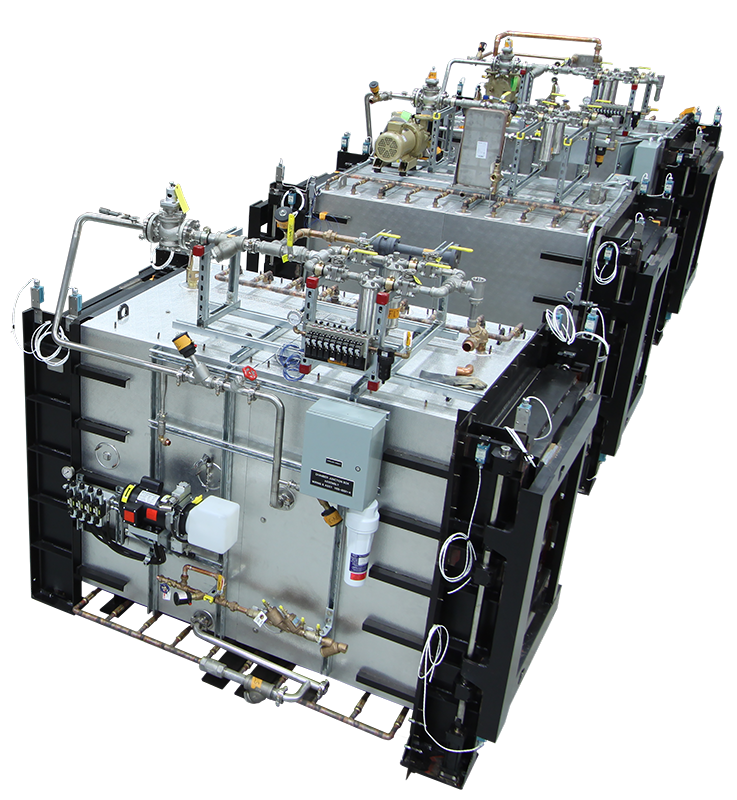

IN-HOUSE TESTING

All conventional one-piece ETC steam sterilizers/autoclaves undergo in-house testing which include the following:

- ASME Hydro Testing

- Vacuum Leak Testing

- Complete I/O Verification

- Instrumentation Calibration

- Door Operation & Safety Testing

- Operational System Testing

- Standard Cycle Runs (high & low temperature ranges)

- Bowie-Dick & Biological Indicator (B/I) Test

DOOR CONFIGURATIONS

ETC offers three unique door designs as standard configurations, eliminating the added cost associated with a customization of the autoclave design. By offering a choice of three designs, it enables our clients to select the best door type that will meet their needs. Each door type has its pros and cons which must be considered before selecting the door type for your facility.

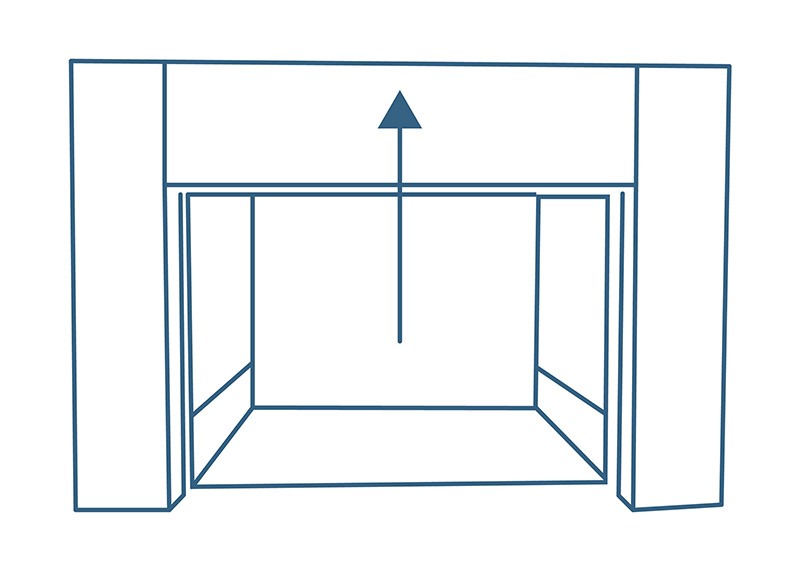

Vertical Rising Door

- Ideal for new construction where interstitial mechanical space is available

- Allows for load staging in front of door

- No loading plates/ ramps required

- Minimal mechanical parts

- Smooth and quiet operation

- Uses less square footage than horizontal sliding doors

- Requires a smaller pit than horizontal sliding doors

- Door Is retained behind heavy-duty door guides during opening

- Requires backup pressure for door seals if power fails

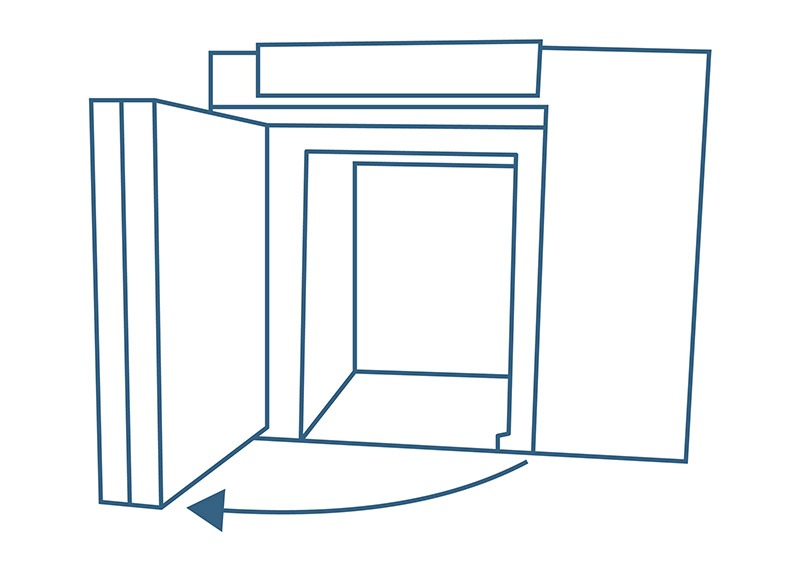

Roller Locking Hinged Door

- The oldest of the door designs with proven performance.

- Uses less permanent square footage than horizontal sliding or vertical doors

- Requires the smallest pit

- Smooth and quiet operation

- Provides positive mechanical locking for the door seal (critical for BSL3 &BSL4)

- Door is retained behind heavy duty blocks when unlocking

- Requires internal or external loading plates/ramps (provided for pit mounting only)

- Loads cannot be staged in front of door

Horizontal Sliding Door

- Ideal for existing or new construction where adjacent space is available

- Requires the largest square footage

- Requires a larger pit than hinged or vertical doors

- Allows for load staging in front of door

- Smooth and quiet operation

- No loading plates/ ramps required

- Minimal mechanical parts

- Requires backup pressure for door seals if power fails.

Easy Glide Sterilizer

Loading Cart

ETC’s innovative Easy Glide sterilizer loading cart was developed to address the space constraints often surrounding floor-mounted autoclaves. Unlike traditional sterilizer loading carts, ETC’s Easy Glide loading cart doesn’t require an external carriage or trolley system.

Accommodates various load sizes and features an ergonomic design

ETC’s Easy Glide loading cart is designed with multiple levels of shelving to accommodate various load sizes and features an ergonomic design that allows for the easy transport of larger loads. The Easy Glide loading cart assembly can be designed for any size chamber and retro-fitted onto any manufacturer’s floor mounted autoclave.

KEY FEATURES

Standard & Custom Designs

While ETC offers standard chamber sizes, we can increase or decrease chamber sizes (incrementally) to optimize available facility space. Additionally, by offering 3 door designs with different space requirements, increased load throughput can often be attained.

Sectional Autoclave Chambers

For difficult to access facility locations, ETC can provide our Mini Bulk & Bulk Autoclaves constructed in 2 – 4 independent sections. The sections are moved into the facility without any disruptions, welded in place, certified, fully tested, and covered by ETC’s 15-Year Structural Warranty. This approach offers a means to replace existing equipment without having to remove doors/frames, walls, or disrupting the ongoing facility operations

Easy Parts Acquisition

Use of non-propriety and commercially available control systems, valves, and mechanical components increases the availability of replacement parts and makes them more affordable than OEM’s proprietary parts.

WHAT MAKES ETC DIFFERENT?

Since 1969, ETC Sterilization Systems has designed, manufactured, and installed EO and Steam sterilizers under one roof, right here in the United States. Our capabilities provide the proper size chamber for optimum sterilizer performance and utility consumption that meet or exceed your specifications.

Learn More