Understanding Steam Sterilization

Understanding Steam Sterilization

Steam Sterilizers, or autoclaves as they’re often called, have been around for hundreds of years with the purpose of rendering materials sterile and safe. These sterile products can be surgical instruments, research materials, pharmaceuticals, supporting packaging equipment, and other products. In this article we will explain what an autoclave actually is, where they’re used, why they’re used and explain the process of what is happening inside an autoclave during a cycle.

An autoclave refers to a pressure vessel that uses high pressure steam to eliminate pathogens that can cause serious diseases in humans and animals. You have likely seen a small autoclave in your dentist’s office, but they are also used by research organizations and even in industrial processes to cure certain materials. Early autoclaves were nothing more than a pressure cooker with manual controls. Today’s autoclaves use the same principles to kill pathogens but with considerable more control and precision due to more sensitive instrumentation and modern computer control systems.

The autoclaves that Environmental Tectonics Corporation (ETC) specializes in manufacturing are used primarily in research vivarium settings where feed, bedding, caging and other lab materials are rendered sterile for research purposes or decontaminated prior to disposal. ETC offers what’s called mini bulk and bulk size autoclaves, meaning they are the largest autoclaves used for non industrial processes. Depending upon the type of research being conducted, the vivarium may be designed with a barrier area, a containment area, or both. For either scenario, the respective environments are highly controlled with protocols established for processing and personnel working in each area. A double door pass-thru autoclave would normally be required for sterilizing items entering the barrier or for items leaving the containment area. For the barrier application, items are sterilized before use, whilst containment items would be sterilized after use and before being discarded or processed for reuse. Since high load throughputs are typically required leaving the laboratory the bulk autoclave is the most efficient way to process large volumes of items.

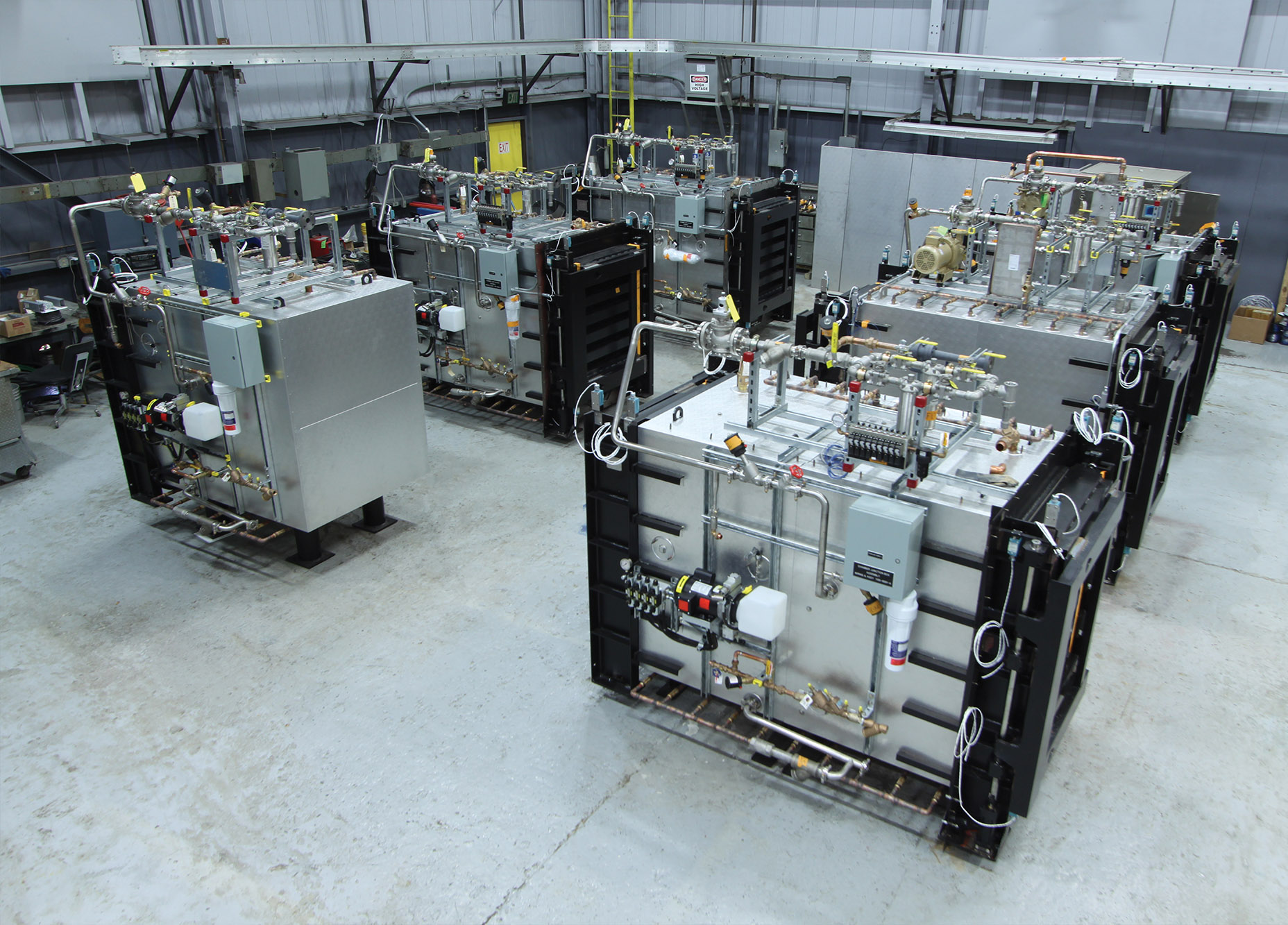

Pictured: ETC Mini Bulk Steam Sterilizers/Autoclaves

To better understand what is happening inside the chamber lets identify a couple major components and track the process of a sterilization cycle. An important component of the modern autoclave is the vacuum pump. This pump provides the means to remove air from the load and facilitate drying of the load. Steam will penetrate the load more quickly in the absence of air, so the removal of air helps reduce overall cycle time. It’s important to note that a vacuum pump isn’t a necessity for the sterilization process to happen. Autoclaves can also run “Gravity Cycles”, where only steam is introduced to promote air removal and air is forced out through the drain in the floor (gravity displacement). This type of cycle will take longer to run but does eliminate the need for a vacuum pump.

Another essential part of the autoclave is the outer channel jacket of the vessel. The outer jacket provides structural support and helps regulate the temperature inside the main chamber of the autoclave. The jacket also helps reduce condensate during heat up to the desired temperature and aids in the removal of moisture during the post vacuum drying phase.

When the autoclave is turned on the first thing that will happen is the steam jacket will begin heating up to the selected temperature by incoming steam. Once a cycle has been selected the air removal stage will begin. During this stage the multiple vacuum pump pull downs, in conjunction with subsequent steam purges, will actively remove air from the load. Air is the enemy of the steam sterilization process and pockets of air can create cold spots that prevent the load from being rendered completely sterile. These purges can be configured in a number of different ways to best fit the cycle being run. This is often referred to as the air removal, pre-vac, or pre-conditioning phase which will provide up to 99.9% air removal. With the absence of entrapped air within the load the selected exposure temperature within the load is quickly achieved.

Upon reaching the programmed temperature, the exposure or sterilization phase of the cycle will begin. This is the phase when pathogens are actively eliminated. During this phase the autoclave will hold a set temperature for a set amount of time. Typical sterilization temperatures are from 121 – 134 deg. C. with exposure times varying from 4 – 60 min. + depending on cycle type, temperature, and load makeup. Some products require a more delicate or sensitive process than others. For example, the cycle for red bag waste could be much more aggressive with a higher temperature cycle than a cycle for animal feeds, since the feed needs to retain its nutrition levels and the lower end temperature ranges are less destructive. If you’re not sure about what cycle you may need, we can help develop one that is ideal for the materials you are working with. At the conclusion of the exposure or sterilization phase, the chamber steam is exhausted to atmospheric pressure. The vacuum pump will once again be turned on to provide drying for the load for a set period of time. At the conclusion of the drying phase, the chamber vacuum is relived with room air via a .2 micron filter, to atmospheric pressure. An end of cycle alarm will indicate that the autoclave door can be unlocked /opened and load removed.

Steam sterilization or autoclaving is not a new process but it is proven, dependable, safe and environmentally friendly. It is also important to note that it is not appropriate for all materials due to the process being high temperature and high pressure. However, for those products that it is right for, there is not a more efficient process. When selecting a sterilizer it is important to make sure you are getting a unit that fully meets your needs – after all, a quality autoclave will be in use for 20 years or perhaps longer. At ETC all of our units are made to order, which means you get the right autoclave based on your specific facility, available space, and type of operations being conducted.

Steam Sterilizers

Since 1969, ETC Sterilization Systems has been a leading provider of Mini Bulk and Bulk Size Autoclaves. If you have a requirement for a large capacity autoclave, ETC would be delighted to help.

Learn More